R.I.D.E.

Maximize your ride bonus

AMG (Automated Machine Guidance) with Smoothride

Technology driven variable depth milling

Precise quantity control

Achieve superior ride improvements

Video courtesy of Topcon Positioning Systems.

What Is R.I.D.E.?

Review. Improve. Deliver. Evaluate. That’s what sums up Coughlin’s newest service offering, RIDE.

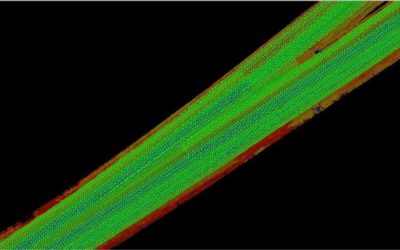

The RIDE service starts with our first step, Review. Coughlin’s team will mobilize our technician to your project to Review the road and collect data. This is done with Topcon’s RD-M1 scanner. The truck mounted scanner collects surface data while it runs at highway speeds. After Review of a pavement surface is complete, it’s time to Improve.

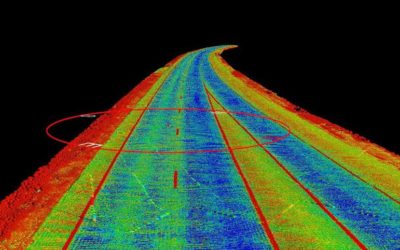

The Improve process is completed by an AMG technician. The Review data is used to create a 3D model of the existing pavement surface. AMG technicians then Improve the surface of the roadway by eliminating bumps and dips while also adhering to the profile and grade requirements of a project. After creating this virtual surface, it is time to Deliver.

To Deliver the virtual design that has been modeled, our team of industry leading operators use Smoothride’s GPS based solution to mill for smoothness. Automated machine guidance technology is used to complete the variable depth milling operation. After work is complete, it’s time to Evaluate.

It’s easy to Evaluate the results of the RIDE system by bringing the RD-M1 scanner out to a completed Smoothride project. Data collection is quick and easy. Analysis of ride improvements can be made in a day or less. The RIDE system is the surefire way to maximize your ride bonus.